Integration between SAP and Infor as part of Infor Cloud Scheduling implementation

Krzysztof Spychalski

Reading time: 6 min

Date: 11 January 2022

Date: 11 January 2022One of our customers faced the challenge of replacing his detailed scheduling system due to a lack of support from Windows 10. The system currently used for short term production scheduling was the custom application developed some years ago and now there is no possibility to run it on Windows 10.

The current systems landscape contains integration with SAP, master planning system and several other applications used for many industry-specific processes. BPX consultant was responsible for this project for integration, so this case study will mainly cover the integration topics.

Challenges

The feasibility phase showed the challenges that will have to be faced during the implementation:

- The factory outage is not allowed during go-live – factory works 24/7/365 and each outage generates measurable costs which everybody wanted to avoid.

- Overcoming the production planners’ fear of the new system – this is always one of the main challenges in IT projects. People are always afraid of new situations. In the beginning, they don’t know how the new system works, how complicated it is etc.

- Comparability of the plans generated by the old and new tools – the old system includes many custom features which are also expected in the new system.

- Number of products and production lines – there are more than 10 production lines and 100s of products to be scheduled; some of the products can be manufactured on the specific lines only; some production lines can be shared.

- Number of systems to be integrated with full data consistency – there were about 10 different applications to be integrated with the new system.

- Number of interfaces to be implemented – there were about 30 interfaces to be developed and implemented, to integrate all systems in the landscape.

- The custom fields in the existing tool – there was a set of custom fields describing materials and resources which were available in the tool currently being used only.

- No changes in the most existing satellite systems are allowed – to reduce the number of places where potential failure can occur, one of the requirements was to deliver data to the satellite systems in the existing format.

Solution

The finding solution started with an as-is analysis. The team detailed described all the requirements to be met. The list of requirements has been split into two groups of requirements: technical and non-technical. This list, later on in the project, has been used as a foundation for the MoSCoW framework.

One of the requirements was to implement the system offered by one of the main players on the market. After several presentations and meetings with potential suppliers decision has been made to use the Infor Cloud Scheduling implemented in Saas (System-as-a-Service) formula.

Infor Cloud Scheduling provided the functionality closest to the customer’s requirements. Additionally, they offered some flexibility in customizing and integration. However, offered system was not fully capable of API, yet. This was the main reason to split the project into two phases.

The first phase was about the implementation of the whole functional scope of scheduling and integration with all required systems without using API.

During the Second phase, all possible interfaces will be switched to use the API offered by Infor.

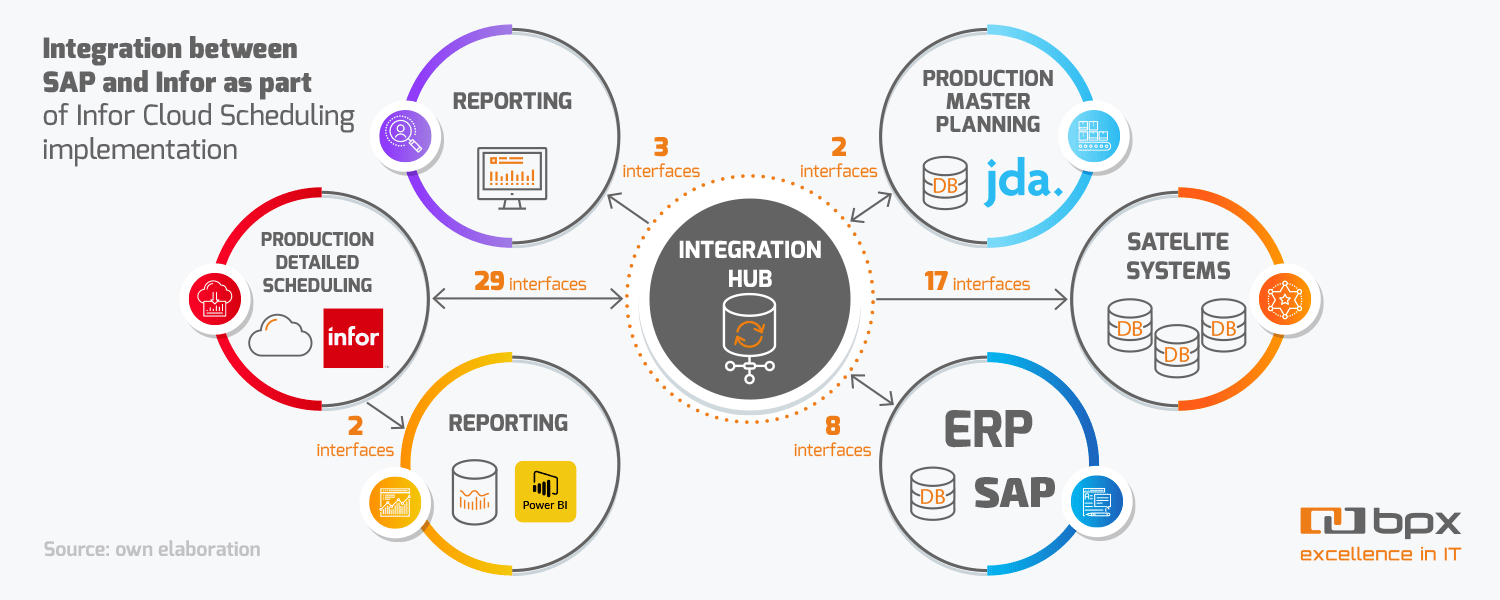

From an integration point of view, the project was quite complex especially because of the number of systems to be integrated and the number of interfaces to be implemented. All systems have been divided into two groups:

- Stream 1 – all systems directly involved in the scheduling process,

- Stream 2 – all satellite systems which expect data generated by the Infor Cloud Scheduling system.

Stream 1, except the Infor Cloud Scheduling system, contained also SAP ERP, master planning system (JDA), MES and custom dashboard system used by production scheduler for production monitoring.

SAP ERP has been treated as the single source of truth in regards to master data and transactional data. SAP ERP was the source for Materials Master Data, BOMs, BOMs Alternatives, Production Versions as well as Purchase Orders, Purchase Requisitions, Stock Transfer Orders and Stock Transfer Requisitions. Additionally, the production progress has been sent to Infor from SAP however, the main source of this data was MES connected to SAP.

JDA as the master planning system was a source of planned orders for the next couple of weeks. Those planned orders have been the basement for a detailed scheduling process.

Infor was also the source of data for stream 1 systems. SAP ERP has been receiving detailed scheduling as process orders created in SAP and sent further to MES. The detailed scheduling has been also sent to the master planning system to be used for any required plan adjustments.

On top of this Infor sends the results of its calculations to the custom dashboard system. This system is being used by production schedulers as well as shop floor workers to monitor the current production situation.

The integration process was carried out through the integration hub where required mappings have been deployed. The Infor Cloud Scheduling system has generated the flat files that were then converted to iDoc XML sent to SAP ERP, CSV files sent to JDA and JSON files sent to dashboard system. The integration hub was also responsible for the transformation of iDoc XMLs from SAP ERP and CSV from JDA to the flat files in the format expected by the Infor Cloud Scheduling system.

Stream 2 contained systems that can not be listed due to NDA. There is only allowed to mention that all of them were sourced in the Infor Cloud Scheduling system and were used for planning different industry-specific elements used in the production. Additionally, there was also integration with Microsoft DataLake deployed as part of stream 2.

Similar to stream 1, also stream 2 systems were integrated through the integration hub. All satellite systems required XML files as the source, so all transformations have been done there. Modern cloud solutions such as Azure Data Factory and Azure Synapse Analytics were used to inject data into DataLake. Then the data collected in DataLake was used in reports created with Power BI.

Benefits and Results

As the solution is still in the early stages of its life cycle, not all benefits have already been revealed. However, some of them, the most important from a technical perspective, can be listed.

First of all considering SAP ERP as the single source of truth in regards to master data and some transactional data, made it possible to manage this data in one place as well as the number of custom fields maintained directly in the scheduling system have been reduced drastically.

Secondly, all implemented interfaces allowed for significant improvement of data quality and consistency. This was directly reflected in the quality of the generated production plans which is the next benefit. The good quality of the generated production plans made it possible to shorten the planning time by about 25-30%.

As was mentioned earlier the solution is still in the early stage so more benefits are expected soon. Additionally, the second phase planned for the next couple of months will help to discover more benefits.

Contact us and find out more about dedicated SAP solutions: bpx@bpx.pl

See recent writings

You drive us to strive for excellence in delivered projects and common challenges. Feel invited to read out blog that provides more in-depth knowledge on our implementations and experience. Read articles about digital business transformation, ERP and Business Intelligence systems. Discover interesting practical applications for future technologies.

- Blog

Navigating the challenges of introducing new software in a company – the role of technology and social dynamics

Contact us!

Let’s talk! Are you interested in our solutions? Our experts are happy to answer all of your questions.

pl

pl